|

|

Visionary

Posts: 3006

San Antonio, TX | I am adding a Stebel Nautilus horn to my Vision.

What bracket did you buy or build to mount it the Vision. Where did you mount it to the Vision?

I am not fond of "one bolt mounts". I was thinking of adding a hose clamp to the bottom of the air compressor to whatever bracket I will build to keep it from moving around.

For power I am going to plug into the battery charging cable. Anyone see an issue with this. The cable will of course be fused.

I just read some posts about the horn but none had pictures. A picture is worth a 1000 words. If you have some pictures of the mount, email them to me.

Radioteacher (delete) at (delete) gmail.com.

I will be making a video of the install.

Ride Safe, Honk LOUD.

Edited by radioteacher 2009-07-19 9:08 PM

|

|

| |

|

Visionary

Posts: 3204

Memphis | KansasGuardsman is the local expert on the Stebel. Have to use part of your original horn for the install. Check his Gallery in the "Parts" album. Contact him for full details. I have one and haven't done the install yet because it's not as straight forward as I thought it would be. |

|

| |

|

Cruiser

Posts: 208

Wichita, Kansas | Hey RT, Check my gallery for some pics. I used a mod on the stock horn mount and used the stock connector to make a plug in. I've got a tech column that I started if you'd be interested in more details. Let me know.

|

|

| |

|

Visionary

Posts: 3006

San Antonio, TX | Thanks! I will take a look.

Ride Safe |

|

| |

|

Visionary

Posts: 3006

San Antonio, TX | KansasGuardsman,

Nice Pictures. I like the wiring diagram and will document it in the Video. I am building my own wiring harness.

I am keeping my stock horn. So to feed the relay I will make a "Y" in my harness. A male blade for the red connector for the stock horn connected to two female blade connectors. One will go on the stock horn and the other will trigger the Stebel relay. I will pull the power from the jack you mentioned.

This would keep the stock horn for three tones and still not require any cutting of the wire harness.

Thanks for your help.

Here is a link to your "parts" pictures.

http://www.vision-riders.com/bb/photos/photo-thumbnails.asp?albumid... |

|

| |

|

Tourer

Posts: 377

O'Neill, Nebraska | Okay...I think I can figure out the wiring; however I have 2 questions.

1). What was done to/with the stock horn in this installation?

2). How did you mount the stebel?

I've had my horn for almost a year and gave up on installing it due to the mounting issue. Any tips would be great.

PS. I've looked at the tips in the Tech forum, but they don't really say how the horn was mounted. Was it a hose clamp, etc? |

|

| |

|

Visionary

Posts: 3006

San Antonio, TX | spursmvp,

I worked on the horn for over an hour in that nasty 103 degree heat yesterday. I was shooting video of the build so I can put it on youtube when I am done.

My Objectives are:

1 Mount the Nautilus and the stock horn for a three tone sound.

2 The stock horn should point to the world not the fairing. (As some stated, the stock horn points to inside the fairing.)

3 Do not cut or tap any wires in the wiring harness.

Here is what I have found out so far.

1. Mounting the Nautilus horn is proving to be a real pain. I know it can be done up and out of the way and above the stock horn but I will have to build a custom bracket. I will try to make some brackets tomorrow out of cardboard to test fitments. Then I will use that to build the heavy sheet metal bracket to hold the new horn.

I will try to mount the bracket with a u-bolt at the top and the stock horn bolt at the bottom. This would be above the stock horn and oil cooler. I do not like the single bolt mount for the Nautilus and will try to make the bracket in a way that will support a hose clamp for the bottom of the Nautilus.

2. I did as some suggest and moved the stock horn to the outside of the stock bracket. I then found that the front left brake lines touch the horn as I turn the front wheel. This is not acceptable. I might build a mount for the stock horn on my new bracket.

3. The plug for the stock horn uses a molded two pin connector. I will have to side tap the positive wire in the harness to control the Nautilus's relay.

I hope to take another run at it today while it is a cool 78 degrees this morning.

If I can figure this out, I will document the bracket. Are you riding tomorrow?

Ride Safe |

|

| |

|

Cruiser

Posts: 104

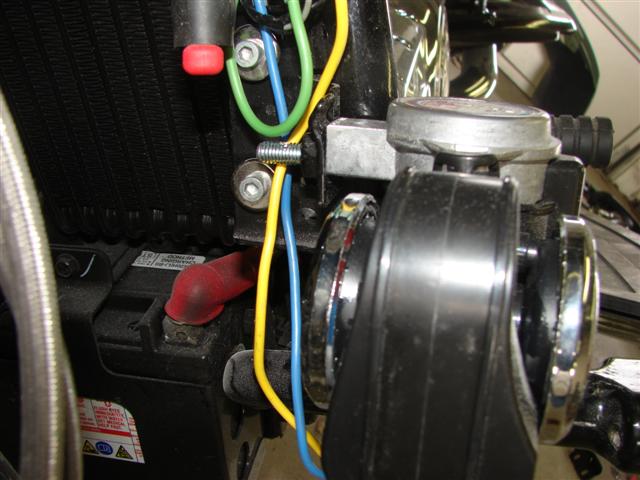

Plainfield Illinois | I don't know that this will help at all but here is an image of the stock horm mount. As an aside, I have lots of hi-res. images taken from all angles of my Vision when it was last naked. I could reduce them to 80 kb. and add to my gallery pics if there is some interest. No rice, no pork, 100% beef. Victory, a REAL motorcycle.

(Capture_122.jpg)

Attachments

----------------

Capture_122.jpg (77KB - 2 downloads) Capture_122.jpg (77KB - 2 downloads)

|

|

| |

|

Visionary

Posts: 3006

San Antonio, TX | That's a nice shot! Do you have one of the other side. This job would be a whole lot easier if i took the fairing off.

Thanks! |

|

| |

|

Iron Butt

Posts: 935

Rockford, IL | About the only way you are gonna accomplish this task is to take the fairng off, its fairly easy and straightforward. Take you less time to take it off than it will to try and work around it. Take a look at my "naked pictures" gallery for my Stebel mounting, There are about 7 or 8 photos. I enlarged the hole in the Stebel mount and grabbed a longer bolt and mounted it to the stock horn bracket that comes off the frame. Then wrapped a wire-tie around the lower part of the Stebel to make it a bit more solid. And by looking at my pictures it appears that you can mount the stock horn bracket on the end of the bolt.

I tossed the stock horn. But before I tossed it I did wire them both to see what they would sound like together. Sounded kinda terrible. The Stebel "overpowers" the stock horn, made it sound more like a "sick" airhorn than anything else. You can purchase the EXACT same horn at Harbor Frieght for a bit less than elsewhere. Harbor Frieght sells them under the name of "Bad Boy" but the stamping/stock/part numbers and such are the EXACT same numbers that are on the Stebel unit. Link http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=94117

Edited by Lotzafun 2009-07-26 10:55 AM

|

|

| |

|

Iron Butt

Posts: 935

Rockford, IL | Link to the horn at Harbor Frieght http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=94... |

|

| |

|

Visionary

Posts: 3006

San Antonio, TX | Lotzafun,

Thanks. I am done with my chores and I am getting ready to work on it again...if the office does not call again.

I did not think about drilling out the stock mounting hole. That would work nice. Plus, I fear that you right about the three tone sound and I will ditch the stock horn.

Ride Safe. |

|

| |

|

Iron Butt

Posts: 935

Rockford, IL | After glancing at my pictures I realized....forgot something...

The design of the Stebel mount doesn't leave much (if any) room to get any type of a tool in there to tighten the bolt. Solved this issue by using two nuts on the end of the bolt. Run one nut down the bolt a bit and then take another nut and run it up against the first nut and then take a wrench to the first nut and it will butt up against the first nut and the bolt will turn/tighten. Going this route will save you the time and hassle of trying to get the bolt "just right" for the Stebel to "slide" over the bolt head tightly. |

|

| |

|

Iron Butt

Posts: 935

Rockford, IL | So...been about 6+ hours...any success yet? Paul?...you there? Hmm....must be outside enjoying being HORNIER  |

|

| |

|

Visionary

Posts: 3006

San Antonio, TX | I worked on many different mounting options and think I found one that is easy to do. Right now the horn is mounted inside the fairing to just one of the bolts from the bodywork that connects to the inner fairing. This is too weak to be a long term mount.

What I propose will look like a flat topped "Y".

The upper left part of the Y will use the stock horn mounting strap. This will connect to the inner fairing bodywork bolt and the horn mounting bolt at the center of the Y.

The upper right part of the Y will be fabricated out of flat stock sheet metal and be about an inch or so longer then the left side. It will also connect to the horn mounting bolt at the center of the Y and the other end will go to the front part of the fairing bodywork and trim. I will add a hole on this bracket to mount the relay.

The top of the strap going down from the center of the Y, connects to the horn mounting bolt at top of this strap. This strap will be bent with a series of 90 degree bends and finally mount to the "stock horn mounting hole" on the frame. I want this strap to support the weight of the horn.

The horn will be held in place at the bottom by a tie wrap or hose clamp to the strap going down from the center.

I need to pick up a side tap for the wire in the harness or find a connector at an auto parts store like the one on the stock horn and some 3/4" strap to build the two parts needed.

I prepped all of the wires on one end so I can cut them to size when the final length is known. I am making notes on all of this so it is taking longer then it would a professional. I will have time on Tuesday to finish up.

This would go faster with a lift. To say the least, I am getting to really know the front end of the Vision.

When done I will document with a PDF and a Video. Now that I have a plan it should go very quickly. |

|

| |

|

Puddle Jumper

Posts: 40

| I thought about using the stock location - but it seemed a tight location - I really wanted the horn facing forward (it's an air horn duh) and I also wanted it higher than the stock horn was to avoid water and other debris being thrown at it.

I decided to run a steel bracket between the tank mount which was plenty meaty and the outer fairing mount - which isn't as strong - but wouldn't be taking much weight. The bracket is pretty stout and locked in between those two locations should keep vibration to a minimum.

I locktighted everything (as I do) and did replace the gas tank mount bolt with a stanless hex head bold to make it easier to get a racheting box wrench around for final assembly.

This whole procedure took a few hours - and is likely more complicated than it needed to be - but when I take these things on I tend to be methodical in my approach. I did use the relay kit as well - always a good idea with a high draw item - and I just clipped the stock connector off - crimped the wires and tapes them for my trigger circuit.

I took a few pics and they can be found in my "Stebel mounting bracket installation" photo gallery.

|

|

| |

|

Visionary

Posts: 1436

| I sure don't want to pee on anyones parade and it looks like you all have this airhorn mounting thing in hand, but consider its use carefully. I use to run airhorns on all my bikes until 5 years ago. Had a lady in a cage, probably 60ish, start to come into my lane. Out of instinct I tapped the horn and it sounded off. She was so startled she looked to see where it had come from instead of moving back the other way into her own lane. Fortunately I had already begun to back off so when she looked and came wizzing into my lane I didn't get pounded. Just a little food for thought, but my opinion is headlite modulators are FAR more effective and prevent the need to use a horn. JMO

ps... there are several self contained air horns on the market that look nicer and are self contained. They will mount easily where I have my coffee cup holder (two bolt holes left lower fuel cell).

Edited by Teach 2009-10-11 7:57 PM

|

|

| |

|

Puddle Jumper

Posts: 40

| A point worth remembering Teach - thanks for that thought.

Generally I don't use my horn unless I have to. Sometimes in an instant -you find you're at defcon 6 and you need to use all the tools you have.

I have also discarded any notion that when I beep my horn - the offending driver will do something intelligent.

Usually it wakes them up - perhaps startles them. (Texting while driving requires concentration!)

Typically they let up on the gas and look around. That's usually gives me enough time/space for me to get the heck out of their way. That's all I hope for.

Occasionally they do something intelligent - like decide to stop before running me down or pulling out in front of me. But its not something I can count on.

I used to be fine with the stock beep-beep horns on my Yamahas, but when I got my V92C years back I remember the day I had to use it and the driver acted like they didn't even hear me. Let's face it - cars are sound insulated, they have stereos and air conditioners cranked- and never mind the important conversation they are having on the phone..

I got a pair of Rivco air horns and use them sparingly. For when you really have to - I would rather be heard. Unfortunately I may PO one or two people in the process? Hopefully not, but if it means avoiding getting hurt or killed - I'll take the chance.

Edited by hgrail 2009-10-11 9:27 PM

|

|

| |

|

Puddle Jumper

Posts: 40

| Here are some higher res pics than what I can put in the album.

|

|

| |

|

Visionary

Posts: 3006

San Antonio, TX | hgrail,

Great job. Here is the final write up on my install.

http://www.vision-riders.com/bb/forums/thread-view.asp?tid=4032

Where did you mount the relay. I put mine on top by the ignition switch. I was thinking on mounting a single air horn on the other side with a lower tone.

I agree with Teach that drivers might be unpredictable when a horn is sounded. A loud horn is just one of the tools I use to get seen and heard in traffic. Sometimes a loud horn is the right tool but nothing works like riding defensively.

Tomorrow I am installing my chrome rear tipover covers. Sounds like a good time to take out the camera and shoot some video.

Ride Safe |

|

| |

|

Cruiser

Posts: 208

Wichita, Kansas | I recently read one of hte many safety articles and it pointed out that if you have time to hit the horn, you have time to brake and evade. Then you can beep the idiot and let them know what just happened. If they don't understand then, they probably wouldn't have understood a few seconds before. But, at least you're safer. |

|

| |

|

Puddle Jumper

Posts: 40

| Yes - I agree drivers are unpredictable.

Perhaps I should have mentioned that defensive riding is #1 on the priority list - unfortunately, as we all know unexpected things happen (and hopefully we learn from them).

In situ I would use the horn as I was already braking/evading. The horn is no substitute for defensive driving and evasive manuvers when needed.

My priorities would be:

1. Divide situations when multiple issues may present

2. Plan to avoid them - options where to go, etc.

3. Evasive manuvers - using horn if it helps (and avoiding it if it may complicate things or make them more unpredictable)

4. If you don't have time for braking/avoiding AND using the horn - drop the horn it's not as important. Generally, it's Less of a priority - and in some situations it can make things worse. If a driver is doing something stupid - but if it is predictable-stupid. Number #1 choice is get out - if you can do so sometimes it's not worth waking up the driver with the horn. Also - don't expect folks to learn how to drive just because somebody blatted them with a loud horn - after the situ is over I think the horn does little more than aggravate people. Having said that, sometimes you're options are really limited - perhaps you've got no-place good to go- and you need the driver to do SOMETHING. That is when you really need the horn as part of your priority escape plan.

I think we have all had things happen that were so quick there was not enough time to consider things - and perhaps not even enough time to hit the horn. If you got out you did good.

As the saying goes "Any landing you can walk away from is a good landing"

For the relay - I mounted it down low on the frame with a cable tie and the excess cable wound up. It's so light I wasn't too worried about it as long as it was out of the way.

Ride safe

Edited by hgrail 2009-10-12 1:08 PM

|

|

| |

|

Cruiser

Posts: 208

Wichita, Kansas | I mounted the relay to the bottom of the horn bell - less wiring that way. Pics in my gallery. |

|

| |

How do I mount the Stebel Nautilus?

How do I mount the Stebel Nautilus? How do I mount the Stebel Nautilus?

How do I mount the Stebel Nautilus?