|

|

Cruiser

Posts: 117

Spring Hill, Tennessee | Sorry guys to have to ask this simple question, but I do not have a service manual yet and I am headed out today to get a socket big enough for the rear axle nut. Can any tell me what size socket I need for this nut?

|

|

| |

|

Visionary

Posts: 2118

Pitt Meadows, BC Canada | Gary - manuals are on-line and 'downloadable' in PDF format. Search the forum for 'Vision Service Manual'. I have it, but it's 37mb and too big to e-mail it to you. |

|

| |

|

Visionary

Posts: 8144

New Bohemia, VA | 1 - 1/16" for us standard folks. I use a craftmans wrench on mine, don't even think about using a socket unless you will only loosen it with the shock-pushrod off. |

|

| |

|

Visionary

Posts: 4278

| Buy a crows foot so you can re torque when done. Use a crescent wrench for loosening the nut. Yes 1 1/16" is the size you want. |

|

| |

|

Visionary

Posts: 8144

New Bohemia, VA | torque - 2 1/2 grunts. it's a lock nut. the key is "DON'T FORGET TO TIGHTEN IT!!!!" |

|

| |

|

Cruiser

Posts: 117

Spring Hill, Tennessee | Thanks to all of you for your help. I figured I only would use the socket for when doing a tire change and removing the swing arm from the shock. I had never heard of a Crow Foot Wrench before (total city boy), but that will be nice for when adjusting belt tension. I can appreciate the locking nut feature of the axle bolt, but if the manual shows a torque spec....I'm gonna be anal and stick with that info. |

|

| |

|

Cruiser

Posts: 58

San Clemente | 65 ftlb's as specified in your owners manual. |

|

| |

|

Iron Butt

Posts: 763

Anderson, IN (48mi NE of downtown Indianapolis) | 27mm work too |

|

| |

|

Visionary

Posts: 1365

Central Maryland | Yea, it's tough trying to torque the axle nut with the stock exhaust in the way. I just got done adjusting my belt tension and discovered that my Craftsman 1/2" drive torque stick was not going to fit in that narrow space, with the 1 1/16" socket attached.

So I gave it 2 1/2 good grunts with a regular ratchet and socket.

|

|

| |

|

Visionary

Posts: 8144

New Bohemia, VA | I just use a boxed in wrench and I use about the same, 2 1/2 grunts.

Edited by varyder 2011-12-10 7:58 PM

|

|

| |

|

Puddle Jumper

Posts: 15

Welch Minnesota | john frey - 2011-10-14 11:26 AM

Buy a crows foot so you can re torque when done. Use a crescent wrench for loosening the nut. Yes 1 1/16" is the size you want.

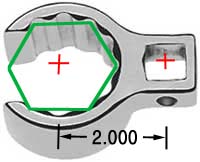

Hi John, I just wanted to let you know you cannot use a crows foot with a torque wrench unless you have the formula for the added leverage you will over torque it because the torque wrench has moved out past the center line of the axle.

Dan |

|

| |

|

Iron Butt

Posts: 802

| If your able to torque with the crows foot at a 90deg angle to the head of the torque wrench, you don't have to correct. If not, the conversion formula is fairly simple.

1. Measure the 'distance between centers' on the crowfoot wrench you're using.

2. On your torque wrench, without the crowsfoot, measure the distance between the center of the torque wrench handle, and the center of the square drive.

3. Determine the desired torque, and plug the values into this formula.

desired torque x torque wrench length

torque wrench length + crowfoot length = torque wrench setting to obtain desired torque

The formula will work with all units of measure.

Marc

|

|

| |

|

Iron Butt

Posts: 612

| varyder - 2011-10-14 11:17 AM

1 - 1/16" for us standard folks. I use a craftmans wrench on mine, don't even think about using a socket unless you will only loosen it with the shock-pushrod off.

I also use a 1 - 1/16" socket. No porblem using my 1/2" torque wrench and 1/2" swivel socket extension without dropping the swingarm!!!

I've never needed a crows foot or anything other than the socket.

|

|

| |

No Manual - Rear Axle Nut Size

No Manual - Rear Axle Nut Size No Manual - Rear Axle Nut Size

No Manual - Rear Axle Nut Size